SERVICES

Calculation & Simulation

Uncertain about your design’s performance? Validate every detail before execution

Calculation & Simulation

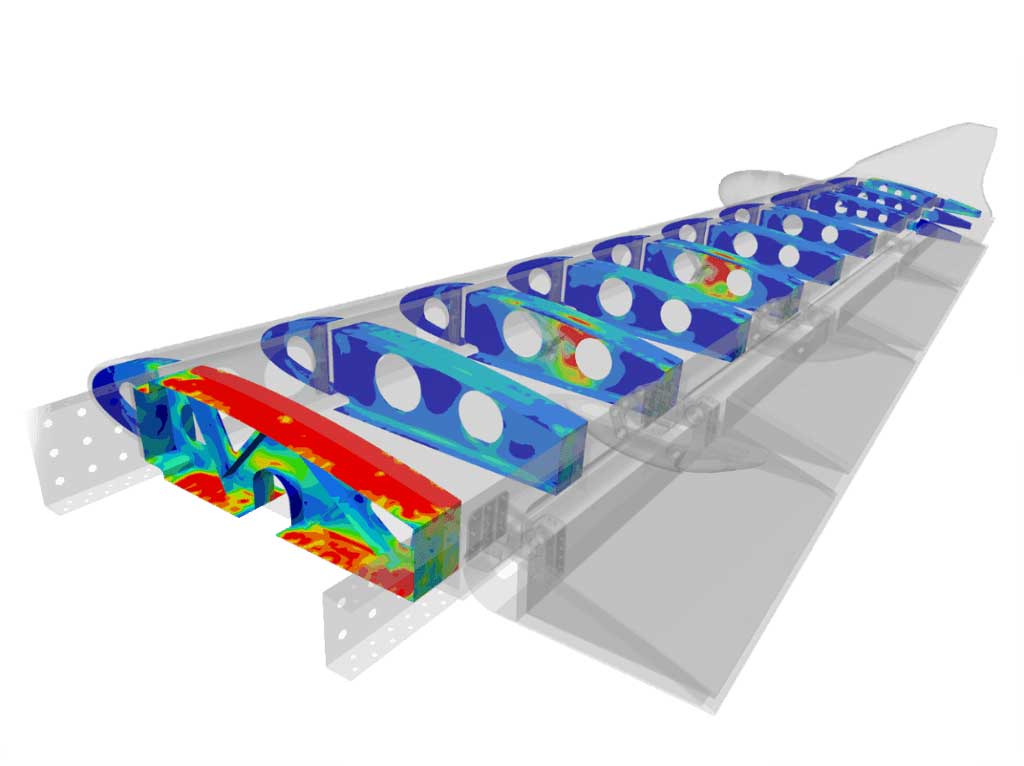

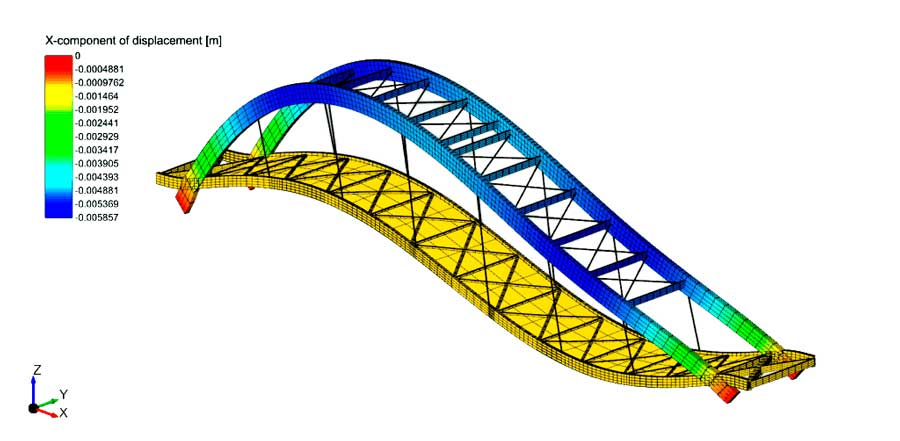

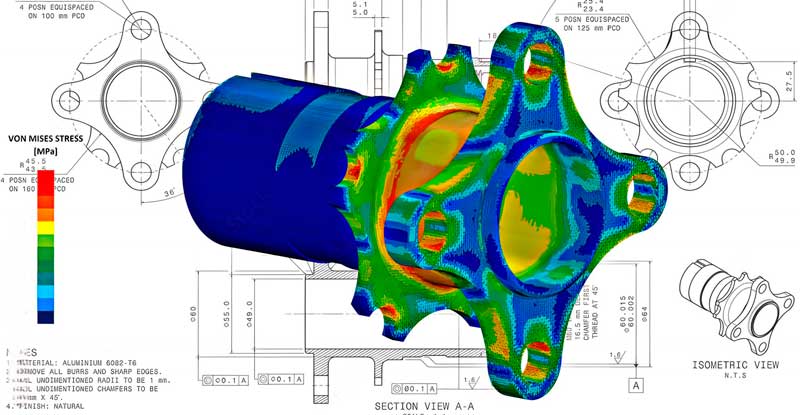

Technical validation through Finite Element Analysis (FEA)

At INGERLAN, we understand that the design and development phase of a product or system often comes with significant uncertainty.

- Will the structure withstand the expected loads?

- How will it perform under extreme temperature conditions?

- Will its dynamic behaviour be optimal?

If these questions go unanswered at the right time, they can lead to costly failed prototypes, production delays, and ultimately, a loss of competitiveness.

That’s why we use the Finite Element Method (FEM) as a key tool to validate, optimise, and ensure the structural, thermal, and dynamic behaviour of your mechanical designs.

Our technical expertise, backed by professional use of Simcenter 3D, Femap, and Nastran-Patran, allows us to deliver accurate and reliable simulations tailored to demanding regulatory standards and functional requirements.

With FEM, we work on both new designs and existing products, applying rigorous engineering criteria in highly demanding industrial sectors. This capability allows us to significantly reduce the need for physical prototypes, prevent failures before they occur, and optimise materials, costs, and lead times.

What is the finite element method (FEM)?

FEM is an advanced methodology that simplifies and breaks down complex problems into more manageable subdomains. This enables us to accurately resolve structural, thermal, or dynamic phenomena, providing detailed insight into how your designs will behave. It is a versatile, robust tool applicable to any geometry or industrial sector, ensuring reliable and optimised results.

Main Applications

Structural validation prior to manufacturing

Structural analysis and design validation

The foundation of your safety

You need certainty that your structures and components will withstand the most demanding conditions, avoiding failure and ensuring safety.

INGERLAN solution: We carry out thorough structural analysis and rigorous design validation, including:

Linear static analysis

Accurate evaluation of stresses and deformations under static loads — essential for validating thicknesses, geometry, and material selection.

Non-linear static analysis

We address complexities such as contact between bodies, material plasticity, or large displacements, to achieve a comprehensive understanding of behaviour.

Bolted and welded joint calculation

Design and validation of critical joints in accordance with standards, ensuring the integrity of structures and machinery.

CE Marking

We perform the structural calculations required by European regulations, enabling you to comply with legislation without the need for costly physical testing.

Lifting and handling calculation

Definition and analysis of handling systems, including the assessment of lifting point arrangements on large structural components to ensure safe lifting.

Machining curve calculation for antideflection

Geometric analysis to compensate for deformations during machining, ensuring dimensional accuracy.

Thermal and Dynamic Analysis

Control the environment around your designs

Temperature variations and vibrations can compromise the performance and lifespan of your products. You need to anticipate and mitigate these risks.

INGERLAN Solution: Our thermal and dynamic analyses provide you with the key insights needed to optimise your designs to withstand these conditions:

Modal analysis

Identification of natural frequencies and vibration modes — crucial for avoiding resonances and vibration-induced failures.

Thermal and thermo-structural coupled analysis

Assessment of heat flow, thermal expansion, and their impact on the stress state of the system.

Seismic analysis

Verification according to ASCE 7-16 standards for structures subjected to seismic events.

Advanced thermal and dynamic simulation

Design optimisation through simulation

Integration with Product Design and Engineering

Your competitive advantage

A lack of integration between design and simulation can lead to longer development times and increased costs. You need an efficient workflow.

The INGERLAN Solution: By integrating FEA into our product design and engineering process, we offer you the following advantages:

Cost reduction

Design optimisation that translates into savings.

Reduced development time

Early simulations that speed up the process and minimise iterations.

Improved safety, reliability, and performance

More robust and efficient products right from the design phase.

Regulatory compliance

We ensure your designs meet all relevant regulations from the earliest development stages.

Seamless workflow between design and simulation

Minimises iterations and shortens validation times.

Better technical decisions

Accurate information from the early stages enables you to make strategic, well-informed choices.

Looking for technical support in finite element analysis and simulation?

At INGERLAN, we apply advanced structural, thermal and dynamic simulation tools to ensure the reliability of your projects.

Get in touch with our team and tell us what you need to analyse.

CLIENTS

They trust us